Comprehensive Guide to Manufacturing High-Quality EPS 3D Wall Panels Essential Machinery and Steps for Success

2025-02-21

Comprehensive Guide to Manufacturing High-Quality EPS 3D Wall Panels Essential Machinery and Steps for Success

At Hebei Haosen Leituo Machinery Technology Co., Ltd., we have over 16 years of experience in the manufacturing industry, providing high-performance machinery that helps you create high-quality EPS 3D Wall Panels . In this article, we will guide you through the entire process of producing EPS 3D wall panels, including the essential machinery needed for superior production quality.

Steps to Manufacture High-Quality EPS 3D Wall Panels:

The process of producing EPS 3D Wall Panels involves several stages, each requiring specialized machinery to ensure the final product meets the highest quality standards. Below is a detailed breakdown of each step:

Step 1: Raw Material Preparation

The first step is to prepare the raw materials required for EPS 3D wall panel production. This includes EPS beads and wire mesh. The EPS beads are expanded to create lightweight, durable panels with excellent insulation properties.

Machinery Required:

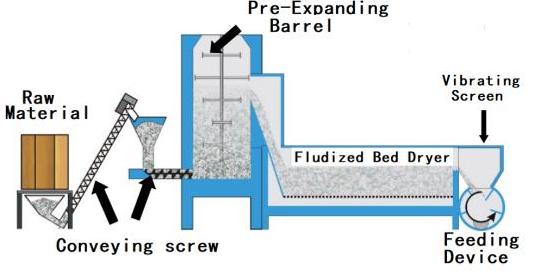

Continual Type EPS Pre-Expander with Fluidized Bed Dryer:

Purpose: This machine expands EPS beads using steam, creating the lightweight material needed for the panels.

How It Works: The pre-expander heats the raw EPS beads using steam, causing them to expand and form the foam required for EPS production. The fluidized bed dryer ensures uniform drying and cooling of the beads.

Step 2: Block Molding

Once the EPS beads are prepared, they need to be molded into blocks that will form the basis for the wall panels. The block molding process allows for the creation of large, uniform blocks.

Machinery Required:

EPS Block Molding Machine with Weighing System:

Purpose: This machine molds the expanded EPS into blocks of specific sizes.

How It Works: The pre-expanded EPS beads are fed into a mold where they are compacted and heated further to form large blocks. The weighing system ensures the right amount of material is used for each mold to achieve consistent panel thickness.

Step 3: Cutting the EPS Blocks

After the EPS blocks have cooled, they are cut into the desired dimensions to create the panels. This step requires precise cutting to ensure uniform panel sizes.

Machinery Required:

Full Automatic EPS Cutting Machine:

Purpose: This machine automatically cuts the EPS blocks into precise panel sizes.

How It Works: The EPS blocks are placed on the cutting platform, where the automatic cutting machine slices them into panels according to preset specifications. This ensures high precision and uniformity in the final product.

Step 4: Adding Wire Mesh for Reinforcement

To enhance the strength and durability of the EPS 3D wall panels, wire mesh is added during the production process. This reinforcement helps the panels withstand the stresses of construction.

Machinery Required:

Purpose: This machine is responsible for creating the welded wire mesh that is embedded into the EPS panels.

How It Works: The machine uses wire coils and a welding process to create a strong, reinforced mesh that is then inserted into the EPS panels. This step is crucial for ensuring that the panels have the necessary strength for construction applications.

Mesh Repairing Machine (Point Welding Machine) :

Purpose: If there are any defects in the mesh, this machine repairs them using point welding.

How It Works: The point welding machine repairs weak spots or breaks in the mesh, ensuring its integrity before it is inserted into the EPS panels.

Step 5: Panel Assembly and Welding

Once the EPS blocks and wire mesh are ready, the panels are assembled. The mesh is embedded within the EPS blocks, and the panels are welded together using a specialized welding machine to ensure they are securely bonded.

Machinery Required:

Vertical Type 3D Panel Machine:

Purpose: This machine assembles the EPS panels with the embedded mesh and performs the necessary welding.

How It Works: The vertical 3D panel machine aligns the EPS blocks with the wire mesh and then uses welding to ensure a secure bond. The result is a solid, well-formed 3D wall panel that can be used in construction projects.

3D Panel Welding Machine (Patented & CE Certified):

Purpose: This machine ensures that the panels are welded with high precision.

How It Works: The machine uses advanced welding techniques to securely bond the wire mesh with the EPS foam, ensuring that the panel is both strong and stable.

About 3D wire mesh panel, and 3D mesh panel machine, please refer the following link:

3D panel production line, pls refer http://www.hbhscn.com/3d-panel-production-line_p39.html

Other types EPS 3D wire panel https://www.hbhscn.com/eps-3d-panel_n317

3D panel fence, pls refer http://www.hbhscn.com/3d-panel-fence_p43.html

3D panel house, pls refer http://www.hbhscn.com/3d-panel-house_p45.html

Zig zag type 3D panels, pls refer http://www.hbhscn.com/zig-zag-type-eps-3d-panels_p44.html

Welded mesh machine, pls refer http://www.hbhscn.com/welded-mesh-machine_p53.html

Vertical type 3D panel machine, pls refer http://www.hbhscn.com/vertical-3d-panel-machine_p54.html

Horizontal type 3D panel machine , pls refer http://www.hbhscn.com/horizontal-3d-panel-machine_p55.html

Raw material and tools about 3D panel house, pls refer http://www.hbhscn.com/raw-material-tools-used-in-3d-panel-building_p58.html

EPS 3D panel machine manufacture workshop, pls refer http://www.hbhscn.com/eps-3d-panel-machine-icf-blcok-machine-workshop_nc3

EPS 3D panel machine container loading pictures, pls refer http://www.hbhscn.com/container-loading-pictures_nc7

Tags : EPS 3D Panels EPS Panels High-quality 3D Wall Panels

PreviousThe Best 3D EPS Welded Mesh Panel Machines A Comprehensive Guide Introduction

NextRevolutionizing Construction with EPS 3D Panels Strength, Efficiency, and Innovation