The Best 3D EPS Welded Mesh Panel Machines A Comprehensive Guide Introduction

2025-03-05

The Best 3D EPS Welded Mesh Panel Machines A Comprehensive Guide

Introduction

For over 16 years, our factory in China has been at the forefront of manufacturing high-quality 3D EPS Welded Mesh Panel Machines. We provide complete production lines for clients, guiding them from selecting the right machines to designing their factories and training their workforce. Our goal is to ensure that customers achieve success from their very first project.

3D EPS wall panels are widely used in modern construction due to their lightweight nature, high insulation properties, and ease of installation. Producing these panels efficiently requires advanced machinery, and there are three main types of 3D EPS Welded Mesh Panel Machines:

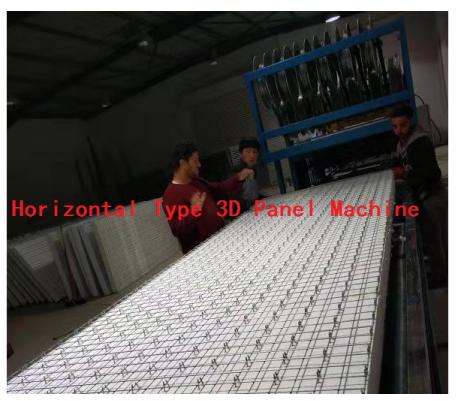

A. Horizontal Type 3D EPS Welded Mesh Panel Machine

B. Vertical Type 3D EPS Welded Mesh Panel Machine (Diagonal wire feeding from galvanized steel reels)

C. Vertical Type 3D EPS Welded Mesh Panel Machine (Diagonal wire feeding from pre-cut steel wire)

In this article, we will explore the advantages and disadvantages of each type to help you make an informed decision for your business.

A. Horizontal Type 3D EPS Welded Mesh Panel Machine

Disadvantages:

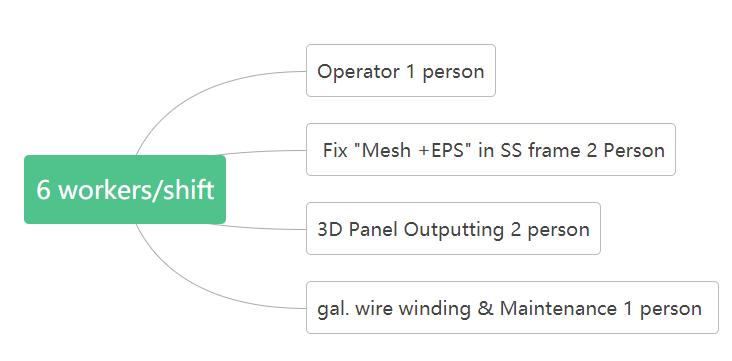

1. Higher Labor Requirements: Requires more workers to manually fix the EPS, mesh, and frame together before welding. One shift typically needs 5-6 workers.

2. Larger Space Requirement: Occupies more floor space, increasing workshop rental costs.

3. Difficult Maintenance: Engineers must access parts beneath the machine, making maintenance and repairs cumbersome.

4. Challenging Waste Management: EPS scrap accumulates under the machine, making cleaning inefficient.

5. Lower Efficiency: The machine experiences idle time during welding due to frame adjustments.

6. Longer Changeover Time: Adjusting for different panel sizes requires fixing screws and modifying machine settings, leading to delays.

B. Vertical Type 3D EPS Welded Mesh Panel Machine (Diagonal wire feeding from galvanized steel reels)

Advantages:

1. Lower Labor Costs: Requires only three workers per shift—one for operation and wire winding, one for panel feeding, and one for output handling.

2. Easier Maintenance: No need to access components underneath the machine.

3. Space-Efficient Design: Occupies less floor space compared to the horizontal type.

4. Faster Changeover: No need to adjust screws when changing panel thickness and length.

5. Higher Production Efficiency: Continuous operation without idle time, resulting in greater output.

6. Easier Cleaning: Waste EPS scraps are easier to remove.

C. Vertical Type 3D EPS Welded Mesh Panel Machine (Diagonal wire feeding from pre-cut steel wire)

Advantages:

1. Lower Labor Costs: Requires three workers per shift—one for operating both the welding and wire straightening machines, one for feeding panels, and one for output handling.

2. Simpler Maintenance: No need to go under the machine for adjustments or part replacements.

3. More Compact Layout: Saves more space than the other two types.

4. Higher Efficiency: Continuous operation with no machine idling.

5. Easier Cleaning: Waste management is simpler and more efficient.

6. Faster Production Speed: Wire straightening and welding occur simultaneously, reducing processing time.

7. Lower Welding Failure Rate: Ensures stronger and more consistent welds, reducing the need for rework.

8. Superior Panel Quality: Results in higher precision and lower internal stress, ensuring durable and stable panel

Disadvantages:

· Longer Changeover Time: Changing the wire hopper for different EPS thicknesses takes around 3-4 hours, but this process is done in batches and not frequently.

Conclusion: Choosing the Right Machine

Based on our extensive experience, we recommend:

· Type B (Vertical with galvanized steel reels) for EPS core thickness between 60-150mm.

· Type C (Vertical with pre-cut steel wire) for thicker panels (200mm or more), as it offers superior precision and efficiency.

We do not recommend the horizontal type due to its higher labor costs, larger space requirements, and maintenance challenges.

Why Choose Our 3D EPS Panel Production Line?

As a leading manufacturer in China with over 16 years of experience, we provide complete turnkey solutions for clients, including:

A. Machine selection and consultation to match your production needs.

B. Factory design and layout to optimize efficiency.

C. Comprehensive worker training to ensure smooth operations from day one.

D. After-sales support and maintenance for long-term reliability.

Our advanced technology ensures that our machines deliver high precision, lower labor costs, and maximum efficiency, making your investment highly profitable.

Get in Touch

If you are looking for a high-quality 3D EPS Panel Production Line, contact us today to discuss your requirements. We are committed to providing the best solutions to help you achieve success in the construction industry.

WhatsApp: +8615633821221

Tags : 3D EPS Panel 3D EPS Welded Mesh Machine

PreviousQuality of EPS 3D Panels Starts with Manufacturing and Machinery