PRODUCT DESCRIPTION

EPS Cement sandwich panel production line

EPS cement sandwich panel production line consist of mixing system, EPS pre-expanding system, Cement micro-expanding system, automatic feeding system, core material mixing system, pouring system, mold forming carrier, molding circulation system, splitting system from mold.

The production capacity mainly depending on the quantity of the mould.

EPS cement sandwich panel production line consist of the following machines.

| No. | Product Name | Type | Use | Qty |

| 1 | Twin shaft mixer |

JDC500 JS500 JS750 JS1000 |

Mixing different raw material , choose Model No. according to production capacity requirement. |

1set |

| 2 | molding vehicle |

Overall dimension:4100*1800*3100 Motor:3KW Rail distance:130M |

Sandwich panel forming molding. The mold qty should be according to output requirement. |

12set |

| 3. | EPS pre-expanding machine with bed dryer | Model No.HS-960 | Making EPS beads | 1set |

| 4 |

Steam Boiler and Steam tank |

Electric heating type,oil or natural gas as raw fuel type. |

Support steam for EPS pre-expanding machine. |

1set |

| 5 | Cement Foaming machine |

Overall Dimension: 2800*1200*1500 |

Foaming the cement,reducing the weight | 1set |

| 6 | Handcart |

|

Transport the raw material | 2set |

| 7 |

Water pump |

|

Mixing the water. | 2set |

| 8 | Hose pump |

|

Transport the mixed-material | 1set |

|

|

|

Max flow rate:32,200 L/h Flow rate:6.7L/rotation Max pressure for the outlet:16ba Inner dia for the hoseof pump: Φ65mm Lubrication oil:20L |

to the automatic molding vechile for forming |

|

| 9 | Air compressor |

|

Spray release agent | 1set |

| 10 | Sandwich-panel disssembling machine |

|

After forming, discharge the sandwich-panel from the machine |

|

| 11 | Liquid type Electric measure |

|

|

|

|

12 |

Electric measure for powder-type material, hopper for measurement |

|

|

|

| 13 |

Installing machine tools |

|

|

1set |

| 14 |

Forklift |

|

Loading panel, transport raw material. |

1-2se |

FAQ

1.What is the raw material for EPS/Calcium Silicate sandwich panel?

1)Main material: Calcium Silicate board, cement, EPS beads.

2)425# cement:approx USD52/ton

3)EPS grain :USD2.6/KG(new material); USD1.2/KG(recycling material)

4)Calcium Silicate board: APPROX USD4/PC for 1.22 * 2.44 * 5mm.

The above is just for your reference, should be depending of the price of your local.

2.What is the profit for this kind EPS Grain and Calcium Silicate board sandwich panel?

According to China market, the production cost is approx USD6.35/M2,and market price is USD12.5/M2(For 90mm Thickness)

3.How much time does it take for pouring one complete mould machine?

Approx 5 mins or so for one set mold machine.

4.Do we need vibrating after pouring?

According to our experience, we don’t suggest vibrating.

Because after vibrating, it will not uniform for the density. And vibrating is not good for the calcium silicate board.

5.How do we ensure that the slurry is well settled in the vertical moulding machine as there is no vibrator being used?

Pouring of concrete, it uses pump to input gradually, the core is voidless,no empty.

6.How long will it take from the pouring to the demolding?

It depends on the local temperature. For some hot place, it is 6-8hours/cycle;for some cold places, it will require 12 hours/cycle.

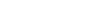

7.How do you open the mould after curing?

8.How much is the curing time for the panels?

For the curing time, it usually takes one week after demolding from the mold machine.

9.How do you ensure that the calcium silicate board sticks properly to the concrete .Also as it gets wet , how its strength is ensured?

1).In the mortar ,we put not only cement and EPS granular, there are also some additive,like consturcion glue powder and HPMC.

The funtion of glue powder it is to add the viscosity of the mortar. The function of the HPMC is for add the strength of the panel.

2)Cement is silicate cement , and the calcium silicate board is also belong to silicate.

3)So the calcium silicate board is easily stick properly to the concrete.

10.How can I get an effective price?

Tell us the specifications and the output required.

11. You provide which service for this project?

Raw material selection and formular

Workshop layout

Production line proposal

Installing machine and training workers

Guiding the production

Response in time for any problem

Sample house

Concrete block wall panel system, please refer the following link:

Light weight partition wall panel machine, please refer http://www.hbhscn.com/light-weight-partition-wall-panel-machine_p71.html

Concrete block machine, paving brick machine, please refer http://www.hbhscn.com/concrete-block-machines_p74.html

Ligth weight wall panel introduction , please refer http://www.hbhscn.com/light-weight-wall-panel_p72.html

EPS concrete sandwich panel introduction , please refer http://www.hbhscn.com/eps-concrete-sandwich-wall-panel_p75.html

Concrete block introduction , please refer http://www.hbhscn.com/concrete-block_p73.html

Video :

- Foam Cement Sandwich Panel machines

- Automatic EPS Cement Board Sandwich panel Machines

- EPS foam Sandwich Panel Machines

hot tags :

We will give you a quotation within 24 hours.

Product: EPS Cement Sandwich Panel Production Line