PRODUCT DESCRIPTION

PU/PIR Sandwich Panel Production Line Advanced Technology for Superior Panels

Sandwich panels are widely used for protecting and decorating the exterior walls of high-rise buildings and premium office complexes. Our sandwich panel production line offers outstanding performance in insulation, flame retardance, and structural integrity, ensuring durability and safety for modern construction projects.

Manufacturing Process Overview:The production of sandwich panels involves a seamless and efficient process to deliver high-quality results. Here's an overview of the key steps:

1. Decoiler and Transverse Positioning: The process begins with precise coil handling, where the lifting stage adjusts the coil’s position for alignment.

2. Coil Loading and Centering: The coil is securely positioned on the decoiler axle, by automatic expansion and pressing to ensure stability.

3.Material Feeding: The material is fed into the system, preparing it for further processing

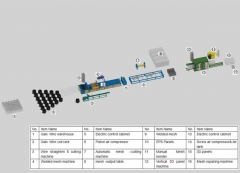

Comprehensive Production System

Our PU/PIR Continuous Sandwich Panel Production Line is an automated and integrated solution combining advanced technologies across mechanics, chemistry, and control systems. The process includes:

1. Decoiling: Accurate and smooth unwinding of materials.

2. Film Coating & Pre-Cutting: Protective film application and material preparation.

3. Roll Forming System: Creating precise panel shapes with consistent quality.

4. Preheating, Foaming, and Solidification: Using heated air recycling ovens for controlled temperature, ensuring uniform PU foaming and curing.

5. Cutting, Cooling, and Stacking: High-precision cutting with band saws, cooling, and stacking for easy handling.

6. Packing: Secure packaging for transportation and delivery.

Main Technical Parameters/Specifications of PU / PlR Continuous Sandwich Panel Production Line

|

ltem |

|

Parameter |

|

Material |

Type |

Color steel sheet; galvanized sheet, Aluminum sheet |

|

Thickness |

0.4-0.8 |

|

|

Width |

s1250(Max) |

|

|

Suitable size of panel |

Length |

2000-16000 |

|

width |

600-1200 |

|

|

Thickness |

30-200 (Not including height of corrugation) |

|

|

Production speed |

3-8 (Adjustable) |

|

|

Valid length of double belt conveyor(mm) |

16000-36000 |

|

|

Work pressure on pouring foam |

150-200 |

|

|

Total power |

About 300 |

|

|

Total size(LengthxWidthxHeight)(mm) |

130000x15000x6000 |

|

Key Features of the Production Line:

1. Versatile Functions: Panels provide excellent thermal and sound insulation, along with fire resistance.

2. Environmentally Friendly Foaming: Using 141B or pentane as foaming agents minimizes environmental impact and enhances worker safety.

3. Precision Engineering: Special double-belt conveyors ensure panels have a smooth surface and uniform thickness.

4. User-Friendly Operation: Controlled by a PLC system with a simple and intuitive interface.

5. Stable and Reliable: High-pressure foaming systems deliver precise measurements and reduce workplace dust, protecting operator health.

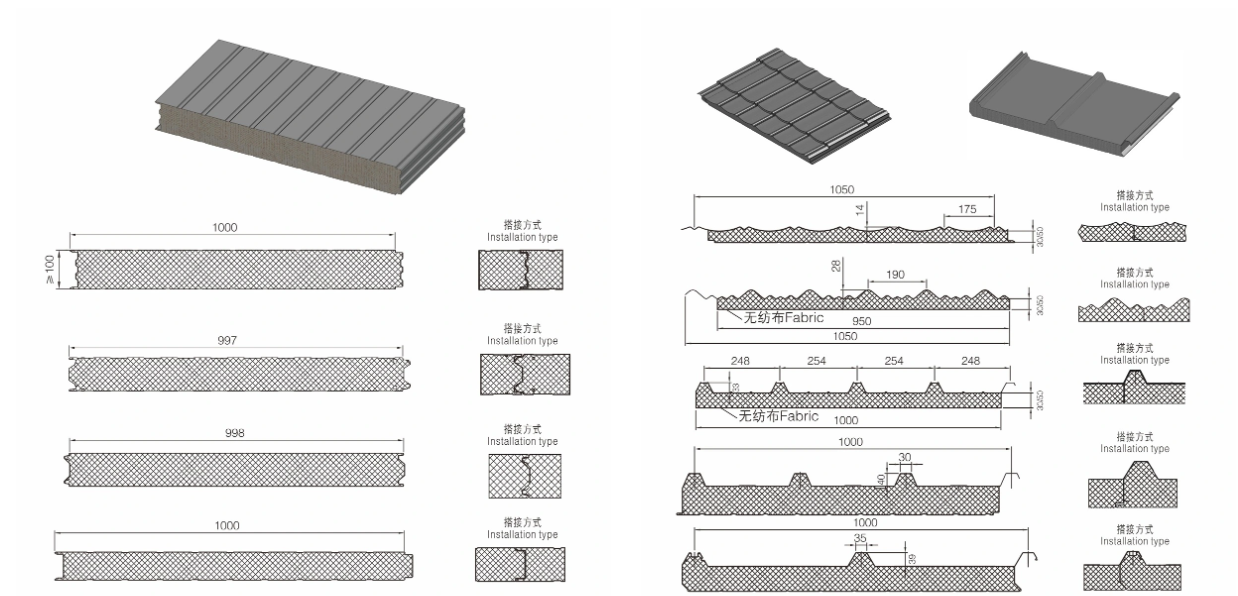

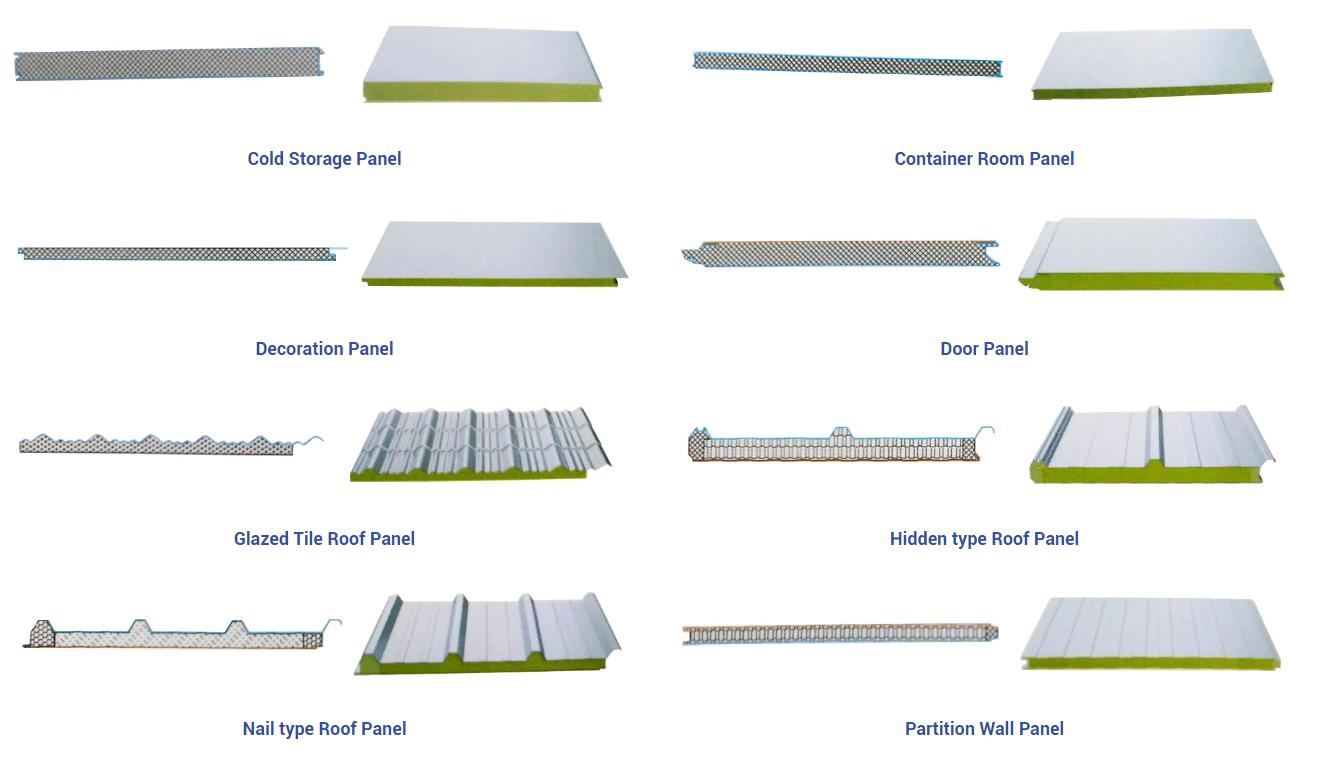

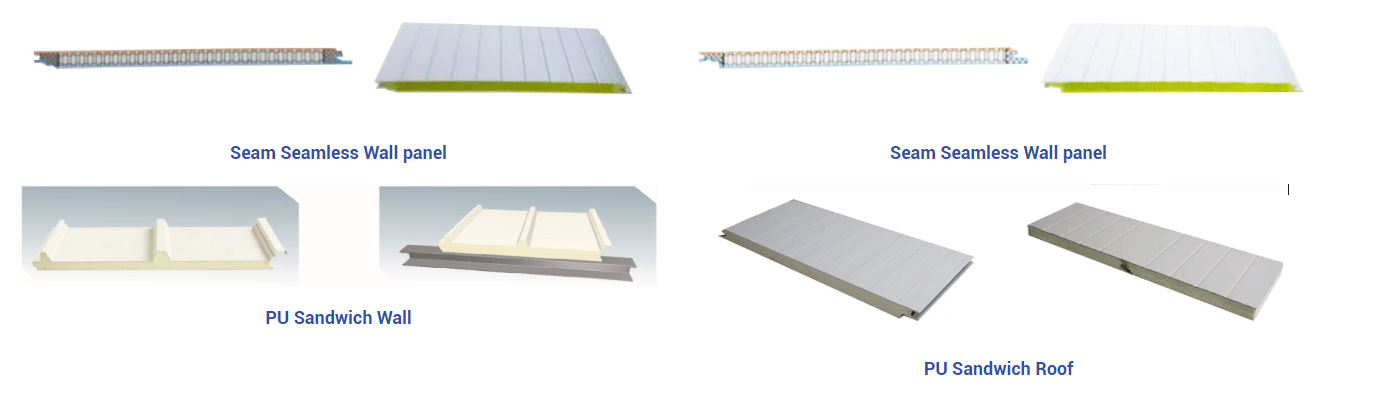

Panel Drawings and Customization:

The PU/PIR Continuous Sandwich Panel Production Line allows customization of panel designs, ensuring they meet the specific needs of your projects.