PRODUCT DESCRIPTION

EPS hot wire CNC foam cutter

Parameters:

Cutting speed: 0-100mm/s

Drawing software: CAD/CAXA

Cutting error: <1mm

Power:220V 50HZ 1PH

Size:1600 x 1100 x 1100

Special size can be made according to customer’s requirement.

Advantage comparing with common foam CNC cutter

1.Accurate – orientation system , the cutting error is less than 1mm, cutting speed to 100mm/s.

2.Unique numerical control program system with patent.

The program can make the machine run without computer, reach one computer control many machines at the same time. (But for common foam CNC cutting, one computer can only control one cutting machine.)

3.Even if the computer failure, the machine can run out of computer.

4. Use Industrial Energy-saving stabilized voltage power source, save energy 80%, the cutting is more uniform and stable.

With current and voltage digital display, isolation with indoor electric, avoid the risk of electrick shock.

5.Use timing belt and ball screw as guide rail, it makes the cutting more precise.

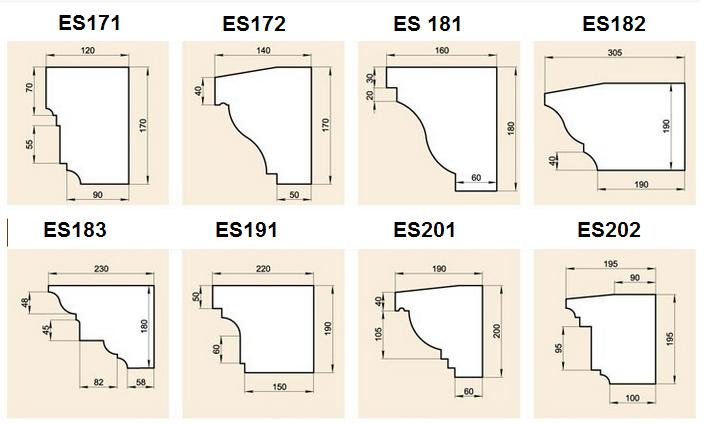

Application

1.Casting industry as lost foam

2.Decoration as cornice ,column etc

3.Packing

Why us?

1. Use Conscience to make and sell machine !

2. More safe, More energy- saving, more precision than the common type!

3. Only high end product, only bottom price!

4. Our price is material cost + our labour cost!

5.Your success, happy ourselves! We are not only making products, but more spread positive energy!

6.112 packing factories + 37 casting factories + 20 decoration factories chose us,we are expecting your joining!

Why make Foam CNC cutter?

At the beginning, we are just a casting factory, we have to use lost foam and buy Foam CNC cutting machine from others. But in using process, the cutting precision is not very high, the cutting size also have 3 mm or so tolerance. So we start to study, improvement and develop our own quality Foam CNC cutting machine, to help more people like us, who have to use high precision EPS CNC cutting machine!

Video